Design Patent Drawing QC Inspection Checklist

Guaranteeing Quality: Essential Inspection Points for Perfect Design Patent Drawings

Ensuring the precision of your design patent drawings is crucial for a successful initial filing. This QC inspection checklist is crafted to guide you through a thorough review process, helping you identify and rectify any potential issues before submission. By meticulously following these inspection points, you can safeguard the quality of your drawings and enhance the likelihood of a smooth patent application process.

1. Do your drawings show Tangent Lines?

- Yes

- No

Conditional Logic Feedback:

- If Yes: Consider avoiding tangent lines. Tangent lines can be misconstrued as claiming ornamental features that do not exist, leading to potential legal challenges. Recent legal challenges, such as the case in Simplehuman, LLC vs. iTouchless Housewares and Products Inc., highlight the potential pitfalls of including such lines in design patent drawings.

- If No: No action required.

2. Did you use an inventor-provided 3D model as source material?

- Yes

- No

Conditional Logic Feedback:

- If Yes: No action required. An inventor-provided 3D model ensures accurate and consistent object appearances across views.

- If No:

- If images were used as source material and a 3D model was created from them, verify that the model accurately reflects the intended design. Errors in the model can lead to inaccuracies in the drawings.

- If an error-prone image-tracing-based drawing process was used, ensure that all objects and configurations are accurately and consistently represented across all views. Manual tracing can introduce errors, so careful review is essential.

3. Did you use a 3D model-based process to automatically generate your drawings?

- Yes

- No

Conditional Logic Feedback:

- If Yes: No action required. The software automatically generates accurate and consistent drawings from the 3D model, eliminating the risk of human error.

- If No: The manual image tracing process is prone to errors. Images often contain perspective distortion, and the drafter may need to make adjustments, increasing the likelihood of mistakes. In the case of Seed Lighting Design Co. v. Home Depot, deficiencies in the drawings due to manual errors led to the invalidation of the patent application. Ensure careful review and verification of manually created drawings to avoid such issues.

4. Did you use a 3D model-based process to automatically disclaim areas with dashed lines in your design?

- Yes

- No

Conditional Logic Feedback:

- If Yes: No action required. Using a 3D model-based process ensures consistent and accurate disclaiming of areas across all views.

- If No: Manually converting solid lines to broken lines across multiple views is error-prone. Drafters need to carefully ensure that the same line or part of a line is consistently converted to a dashed line in all views. This process is challenging and can lead to serious issues, as demonstrated in the case where Plaintiff Times Three Clothier filed suit against defendant Spanx, and the court invalidated two of the design patents due to “a fatal inconsistency” in the dashed lines. Ensure careful review and verification of manually created broken lines to avoid such issues.

5. Did you use Stipple Shading?

- Yes

- No

Conditional Logic Feedback:

- If Yes: Software generated stipple shading is error proof process that ensures accuracy, consistent object appearance, and clear boundaries between shaded and unshaded areas. No action needed.

- If No: Since manually applied line shading is an error-prone process, reviewing each shaded object for accuracy and consistency across views is highly recommended. Avoid excessive shading lines to prevent clutter. Ensure all necessary areas are shaded and boundaries are clearly defined, either by extending shading lines or using dashed boundary lines.

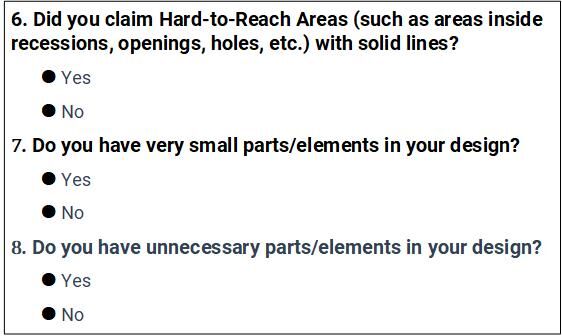

6. Did you claim Hard-to-Reach Areas (such as areas inside recessions, openings, holes, etc.) with solid lines?

- Yes

- No

Conditional Logic Feedback:

- If Yes: Ensure you have sufficient views to fully disclose each surface located in hard-to-reach areas. Consider using sectional views to reveal the characteristics of these surfaces. If possible, it’s best to disclaim all hard-to-reach areas with broken lines to avoid ambiguity.

- If No: No action required.

7. Do you have very small parts/elements in your design?

- Yes

- No

Conditional Logic Feedback:

- If Yes: It is best to remove and completely omit very small parts/elements if possible, as they may appear solid even when represented with dashed lines. Otherwise, consider using zoomed views to fully disclose their details.

- If No: No action required.

8. Do you have unnecessary parts/elements in your design?

- Yes

- No

Conditional Logic Feedback:

- If Yes: If many unnecessary elements are shown in solid lines in your design patent drawings, you risk complicating the disclosure process and potentially introducing functionality issues. For example, the case of Sattler, U.S. Design Patent No. D823,093, highlights the importance of omitting purely functional elements to avoid jeopardizing the patent’s validity on the grounds of lack of ornamentality. The best approach is to omit these elements if possible, or as a second-best option, disclaim them with broken lines to simplify the disclosure process and reduce the emphasis on their functional nature.

- If No: No action required.

9. Do you have complex surfaces in your design (organically shaped, convex, concave, etc.)?

- Yes

- No

Conditional Logic Feedback:

- If Yes: Ensure you properly disclose complex surfaces with appropriate shading and sufficient views, including sectional views if necessary, to clearly depict their characteristics.

- If No: No action required.

Recommended Webinars

Delve deeper into the topics discussed in this article by attending our webinars. These sessions provide further insights and offer the chance to interact with experts in design patent drafting and illustration.

- Design Webinars: Avoiding Non-Correctable Errors in Design Patents:: Discover how to avoid non-correctable errors in design patents and ensure the success of your applications in this informative webinar by IP DaVinci.

- Design Webinars: Handling Advanced Scenarios in Design Patents: Explore strategies for handling advanced scenarios in design patents in this insightful webinar by IP DaVinci, enhancing your ability to navigate complex cases.

- Design Webinars: Cost and Time Saving Tips for Design Patent Drawings: Learn cost and time-saving tips for design patent drawings in this practical webinar by IP DaVinci, aimed at streamlining your patent application process.

Provide Feedback

We value your feedback! Let us know how we can improve or what topics you’d like to see next.

Connect with Mike

Have questions or need support? Connect with Mike for personalized assistance.

Share Your Experience

Found our series helpful? Share it with your network and help others benefit too!